Protein and biomolecules sources for nutritional security and biodiversity

of bakery products in a circular food system

Membrane Extraction Technology

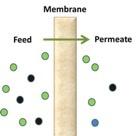

Membrane technology by both polymeric and ceramic membranes is supposed to be among the most useful solutions for applications in food, environmental, pharmaceutical, energy and electronic sectors. A membrane can be defined as a semi-selective barrier; the membrane module acts as a molecular filter allowing the retention of specific molecules and concomitantly the permeation of others across its matrix.

Food sector is the second biggest global industrial market for membranes, after water and wastewater treatment. In this context, membrane filtration is considered with increasing attention for purification and concentration, as well as cold pasteurization and sterilization. This allows obtaining economic advantages in terms of energy consumption, plant simplification and low environmental impact.

Depending on membrane pore size, different pressure driven processes can be performed: reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF) and microfiltration (MF). These processes present several advantages for fractionating and recovering food components in comparison to the conventional techniques: simplicity of plant management, modularity of the system, absence of chemical additives, continuous and adaptable process, mild operational conditions. The membrane facility in PROVIDE Project is composed by a set of four pilot scale plant (MF-UF-NF-RO) equipped with ceramic and polymeric modules (treatment capacity:300-500 L/d), and a flat membrane lab scale plant (capacity 2 to 5 L/d).

References

- Herrero M., Mendiola J. A., Cifuentes A., Ibáñez E., Supercritical fluid extraction: recent advances and applications, Journal of Chromatography A, 2010, 1217, Pages 2495-2511, https://doi.org/10.1016/j.chroma.2009.12.019

- Reverchon E. and De Marco I., Supercritical fluid extraction and fractionation of natural matter, The Journal of Supercritical Fluids, 2006, 38, Pages 146-166, https://doi.org/10.1016/j.supflu.2006.03.020